Unleashing the Power of Robotics: A Comprehensive Guide for Experts and Beginners Alike

Introduction to Robotics

|

| Unleashing the Power of Robotics: A Comprehensive Guide for Experts and Beginners Alike |

The Evolution of Robotics

Robotics has come a long way since the first mechanical automata were designed in ancient times. Initially, our fascination with creating machines that could mimic human actions led to simple devices driven by gears and pulleys. Fast forward to the 20th century, the advent of computers transformed robotics. Technologies like artificial intelligence (AI) and machine learning started to emerge, enabling robots to perform tasks that require perception and decision-making. One notable example of early robotics is George Devol's Unimate, which became the first industrial robot in the 1960s, designed for use in manufacturing. This innovation paved the way for robots to enter various industries, marking a significant shift in how tasks were executed. Today, robots are integral to our daily lives, from robotic vacuum cleaners helping with household chores to sophisticated surgical robots performing life-saving procedures.

Applications of Robotics in Various Industries

As robotics continues to evolve, its applications have expanded exponentially across diverse sectors. Here are some remarkable areas where robotics plays a pivotal role:

- Manufacturing: Industrial robots automate repetitive tasks like welding, assembly, and painting, boosting efficiency and productivity.

- Healthcare: Medical robots assist in surgeries, enhance precision in procedures, and often perform tasks like medication delivery.

- Logistics: Autonomous mobile robots are optimizing supply chains, handling warehouse tasks like sorting and transporting goods.

- Agriculture: Drones and robotic harvesters are revolutionizing farming by enabling precise planting, monitoring crop health, and automation of harvesting.

- Entertainment: Humanoid robots and robotic pets provide interactive experiences, showcasing the delightful side of technology.

With these incredible advancements, robotics is not just a field of innovation but a transformative force shaping the future of work and everyday life.

Understanding Robotics Technology

Types of Robots

When you think of robots, you might picture humanoid figures or robotic arms in factories. However, the world of robotics is incredibly diverse. Let’s explore some of the main types of robots you might encounter:

- Humanoid Robots: Designed to resemble humans, these robots are often used in research and customer service. Their ability to interact naturally with people makes them fascinating.

- Collaborative Robots (Cobots): Unlike traditional industrial robots that operate in isolation, cobots work alongside humans, ensuring safety and enhancing productivity in manufacturing and healthcare settings.

- Domestic Robots: These are your household helpers like vacuum cleaners (Roombas) and lawn-mowing robots, designed to perform daily chores, making our lives easier.

- Autonomous Mobile Robots: Often seen in delivery and exploration tasks, these robots navigate environments without human intervention, showcasing advancements in navigation technology.

Understanding the variety of robots out there opens up exciting possibilities for their applications in different fields, from manufacturing to healthcare and beyond.

Sensors and Actuators in Robotics

Now, let’s dive into what makes these robots functional—sensors and actuators. Sensors are the eyes and ears of robots. They gather information about the environment, which is crucial for the robot's decision-making process. Here are some common types:

- Vision Sensors: Cameras that help the robot “see” its surroundings.

- Proximity Sensors: Detect nearby objects to avoid collisions.

- Force Sensors: Measure force and pressure, allowing delicate handling of items.

Actuators, on the other hand, are the muscles of robots. They convert energy into motion. For instance:

- Electric Motors: Widely used for smooth movements.

- Hydraulic Actuators: Great for heavy lifting and precision tasks.

The seamless interplay between sensors and actuators empowers robots to interact with their environment intelligently and effectively. By understanding these components, you gain insight into how robots accomplish their incredible feats!

Getting Started with Robotics

Choosing the Right Robotic Kit

Embarking on your robotics journey is exciting, but selecting the right robotic kit can make all the difference in your learning experience. With so many options available, it's essential to consider a few key factors:

- Skill Level: Are you a beginner or more advanced? Kits are available for various skill levels, so start with one that matches your current abilities. For beginners, look for kits with intuitive instructions.

- Type of Projects: Think about what you want to build. Do you prefer simple robots that follow lines or more complex ones that can navigate obstacles? Kits focused on specific projects can help guide your learning.

- Components Included: Ensure the kit includes everything you need—sensors, motors, and a microcontroller. Some popular kits for beginners include:

- LEGO Mindstorms: Great for building a wide range of robot types.

- VEX Robotics: Offers educational kits that emphasize programming and engineering principles.

Choosing the right kit sets the stage for a fun and educational experience as you build your first robot!

Learning the Basics of Programming Robots

Once you have your robotic kit, it’s time to dive into programming! Don’t worry if coding feels overwhelming at first; with the right approach, anyone can learn.

- Start Simple: Familiarize yourself with basic programming languages like Scratch or Python, which are user-friendly for beginners. Create small projects to see immediate results.

- Utilize Resources: Take advantage of online courses and tutorials. Websites like Code.org and Khan Academy offer interactive lessons that make learning enjoyable.

- Experiment and Iterate: Programming involves trial and error. Don’t hesitate to tweak your code, see what works, and learn from mistakes.

By choosing the right robotic kit and embracing programming basics, you’ll be well on your way to creating impressive robotic projects that will deepen your understanding and spark your creativity in the world of robotics!

Advanced Concepts in Robotics

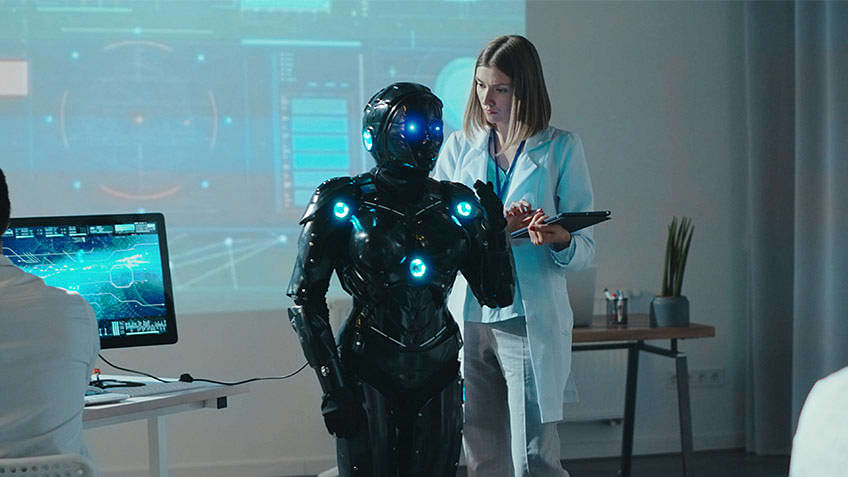

Artificial Intelligence in Robotics

As we delve deeper into the world of robotics, one of the most exciting frontiers is the integration of Artificial Intelligence (AI). In its essence, AI allows robots to replicate tasks that require human-like intelligence. Imagine a robot not just following pre-defined commands but making real-time decisions based on its environment—this is the magic of AI in robotics.

- Real-time Decision-making: With AI, robots can analyze vast amounts of data from their sensors and make informed decisions. For example, a delivery robot can assess traffic conditions and choose the best route to its destination.

- Enhanced Interaction: AI-powered robots can understand and respond to human emotions, making them ideal for customer service roles or companionship.

AI is transforming robots from mechanical helpers into intelligent collaborators, making them more adaptable and functional in our daily lives.

Machine Learning for Robotics

Building on the foundation laid by AI, Machine Learning (ML) is a subset that plays a critical role in enhancing robotic capabilities. Through ML, robots can learn from experience and improve their performance over time without being explicitly programmed for every scenario. Here’s how Machine Learning benefits robotics:

- Adaptability: Robots can learn to perform tasks more efficiently. Consider a robotic arm that learns to pick objects of varying shapes and weights; it can adapt its techniques based on previous successes and failures.

- Predictive Maintenance: ML algorithms can predict mechanical failures by analyzing sensor data and usage patterns, allowing for proactive maintenance and reduced downtime.

The combination of AI and ML is ushering in a new era of robotics, where machines can not only execute tasks but also learn from their environments, enhancing their autonomy and efficiency. As you explore these advanced concepts, think about how they can reshape various industries and everyday applications.

Building Your Own Robot

Designing the Robot

Designing your own robot is one of the most exciting steps in the robotics journey. This phase is all about creativity and problem-solving as you envision how your robot will function and what it will do. Here’s how to get started:

- Define the Purpose: What do you want your robot to accomplish? Whether it's a simple line-following robot or a more complex autonomous machine, having a clear goal will guide your design choices.

- Sketch Your Ideas: Grab a piece of paper and start sketching! Visualizing your robot can help clarify how each component will fit together. Don’t worry about getting it perfect—this is just a draft.

- Select Components: Based on your robot’s purpose, choose the right components. For example, if your robot needs to navigate, consider adding sensors like ultrasonic or infrared to detect obstacles. Make a list of all necessary parts, including:

- Motors: For movement.

- Microcontroller: To process inputs and control functions.

- Sensors: To gather environmental data.

This design phase sets the foundation for your project's success, so take your time and think through your choices.

Assembling the Components

Once your design is ready, it's time to assemble the components. This is where your robot starts taking shape! Here’s how to approach the assembly:

- Gather Tools: Ensure you have all the necessary tools, like screwdrivers, pliers, and any specialized tools needed for your components.

- Follow Your Plan: Use your sketches and parts list to guide you. Start by constructing the base of your robot, ensuring the motors are securely attached.

- Connect Electronics: Carefully wire your components according to your schematic. Pay attention to power requirements and ensure the right connections between the microcontroller, sensors, and motors.

- Test As You Go: After assembling a few parts, test functionality before moving on. This might save you time and trouble later if something doesn’t work as intended.

By designing intentionally and carefully assembling each component, you’ll soon see your robot come to life, ready to perform the tasks you envisioned!

Programming Robots

Languages Used in Robotics Programming

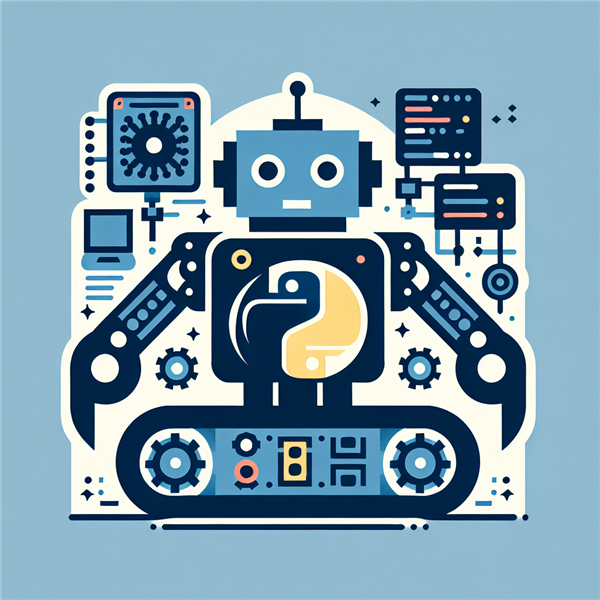

As you dive into the world of robotics, one crucial aspect you'll encounter is programming. Just like humans communicate using languages, robots rely on programming languages to understand instructions. Here are a couple of the most popular languages used in robotics:

- Python: Widely praised for its simplicity and readability, Python is an excellent choice for beginners. It has extensive libraries (like OpenCV for computer vision) that make it easy to program complex tasks. Plus, its straightforward syntax helps you focus more on concepts rather than getting lost in complex code.

- C++: Often used for high-performance applications, C++ allows for detailed control over system resources. It's commonly employed in scenarios where speed and efficiency are critical, such as real-time robotics and firmware development. Although it has a steeper learning curve than Python, it offers greater control for sophisticated robotic systems.

These languages enable developers to build, program, and control robots effectively, paving the way for innovation in automation.

Writing Code for Robot Control

Once you’ve chosen a programming language, the next step is writing the code to control your robot. This can seem daunting at first, but breaking it down into manageable pieces can help.

- Start Small: Begin with simple commands. For example, writing a basic script to make your robot move forward or backward. Experimenting with these commands builds confidence.

- Use Libraries: Take advantage of existing libraries tailored for robotics. Libraries like ROS (Robot Operating System) provide essential tools and frameworks that simplify the coding process, allowing you to focus on your robot's unique features.

- Test Iteratively: After writing your code, upload it to your robot and run tests. Debug as needed, adjusting parameters and configurations to achieve the desired behavior.

By mastering these programming languages and writing effective code, you'll empower your robot to perform a variety of tasks, unlocking endless possibilities for creativity and innovation in your projects!

Testing and Troubleshooting

Testing Robot Functionality

After dedicating time to design, assemble, and program your robot, it’s time for the fun part—testing! Testing functionality helps you ensure everything works as expected before taking your robot for a spin. Here are some effective testing strategies:

- Conduct Basic Function Tests: Start with simple commands to verify that each component, like motors and sensors, operates individually. For instance, check if the robot can move forward or backward as intended.

- Create a Controlled Environment: Set up a clear area free of obstacles to test your robot’s navigation. This helps you observe how well it avoids barriers or follows a path.

- Incremental Testing: Instead of testing everything at once, introduce features gradually. For example, first test basic movement, then add sensors, and finally evaluate more complex behaviors like object detection.

Testing can often feel like a trial-and-error process, but it’s an essential step in ensuring your robot performs reliably.

Troubleshooting Common Issues

Like any technology, things can go awry. Here are some common issues you might face while testing your robot, along with troubleshooting tips:

- Robot Not Moving: If the robot is stationary, check the power supply and ensure the batteries are charged. Also, verify motor connections and check for any loose wires.

- Sensor Failures: Sensors may not detect objects if they’re obstructed or misaligned. Clean the sensor lenses and recalibrate as necessary.

- Erratic Behavior: If your robot moves unpredictably, inspect the code for errors or logical flaws. Debugging your programming and adjusting parameters can often solve this issue.

Troubleshooting can be frustrating, but each challenge presents a learning opportunity. By testing and debugging your robot thoroughly, you'll deepen your understanding and enhance your future projects! Happy tinkering!

Exploring Robotic Automation

Robotics in Manufacturing

As we continue our journey through the fascinating world of robotics, one area where robots have made a significant impact is in manufacturing. Robots are transforming traditional manufacturing processes, enhancing efficiency, and reducing costs. Here’s how they’re doing it:

- Increased Productivity: Robots can work tirelessly around the clock without breaks, making them ideal for tasks that require precision and consistency. For example, assembly line robots are widely used to perform repetitive tasks like welding, painting, and assembly, significantly increasing output.

- Safety and Quality Control: By handling dangerous or hazardous tasks, robots reduce the risk of workplace injuries. Moreover, with advanced sensors and vision systems, they can maintain high levels of quality control, ensuring that products meet strict standards.

- Customization: With collaborative robots, or cobots, now in the mix, manufacturers can produce customized products efficiently. Cobots work alongside humans and are designed for flexibility, allowing them to adapt to different tasks easily.

This shift towards robotic automation in manufacturing not only revolutionizes production but also opens up new job opportunities in robot programming, maintenance, and oversight.

Robotic Process Automation

Moving beyond manufacturing, Robotic Process Automation (RPA) is another exciting application of robotics that is reshaping various business processes. RPA involves the use of software robots (bots) to automate routine tasks typically performed by humans. Here’s why it’s gaining traction:

- Efficiency and Accuracy: RPA bots can handle tasks such as data entry, invoice processing, and customer queries with remarkable speed and accuracy. They reduce the chances of human error, which can lead to costly mistakes.

- Cost Savings: By automating mundane tasks, organizations can reallocate human resources to more strategic activities, keeping operational costs low and driving innovation.

- Scalability: RPA allows businesses to scale operations without significantly increasing overhead costs. With bots handling repetitive tasks, companies can quickly adapt to changing workloads.

The integration of robotics in both manufacturing and your day-to-day business processes demonstrates the immense potential of robotic automation. It’s an exciting time to be involved in this evolving field, as technologies advance and new opportunities emerge!

Ethical Considerations in Robotics

Privacy and Security Concerns

As we integrate robotics into various facets of our lives, privacy and security concerns inevitably arise. The use of robots, particularly those equipped with artificial intelligence, can lead to significant implications for personal privacy. Here’s what you need to consider:

- Data Collection: Many robots rely on cameras and sensors to navigate and perform tasks, which can result in massive amounts of data being collected. For instance, a security robot may record video footage continuously, raising concerns about who views this data and how it's used.

- Hacking Risks: Just like any connected device, robots can be vulnerable to cyberattacks. If a malicious actor gains access to a robotic system, they could compromise sensitive data or even manipulate the robot’s operations. This is a crucial concern, especially in sectors like healthcare and manufacturing.

To mitigate these issues, it's essential to develop robust privacy policies and apply stringent security measures to protect data integrity and user privacy.

Ethical Use of Autonomous Robots

Moving from privacy to the broader implications, the ethical use of autonomous robots is a topic worthy of our attention. As robots become more autonomous, they raise questions about decision-making, accountability, and ethical considerations:

- Decision-Making Algorithms: Autonomous robots are increasingly required to make decisions independently, such as self-driving cars determining how to respond in emergency situations. The ethical dilemmas here are profound: Should a robot prioritize the safety of its passengers over the pedestrians?

- Accountability: When negligent actions occur—like a malfunctioning delivery robot causing an accident—who is held accountable? Is it the manufacturer, the programmer, or the operator? Establishing accountability frameworks is critical in addressing these questions.

As we navigate the ethical landscape of robotics, it’s important to foster discussions that center on developing guidelines and standards for their ethical use. Balancing innovation with responsible deployment is essential for a future where robots enhance our lives without compromising our values.

Future Trends in Robotics

Soft Robotics

As we gaze into the future of robotics, one of the most exciting developments is soft robotics. Unlike traditional rigid robots, soft robots are made from flexible, compliant materials that enable them to safely interact with humans and delicate objects. Here's why this trend is captivating engineers and researchers alike:

- Enhancing Safety: Soft robots can adapt their shape and movements, minimizing the risk of injury to humans. For instance, a soft robotic gripper can gently handle fragile items without causing damage—ideal for industries like food packaging or healthcare.

- Mimicking Nature: Soft robotics is inspired by natural organisms, such as octopuses and earthworms. This biomimetic approach allows for creative solutions in design and movement, opening up new possibilities in how robots navigate complex environments.

- Versatile Applications: From wearable robots that assist individuals with mobility challenges to robotic arms that can conform to various shapes, the applications of soft robotics are expansive. This adaptability is transforming fields such as rehabilitation and automation.

As researchers continue to explore materials and designs, soft robotics is poised to redefine how we think about and utilize robotic systems.

Human-Robot Collaboration

Continuing the exploration of future trends, human-robot collaboration is set to revolutionize various industries by enhancing productivity and efficiency. This collaboration isn’t merely about robots replacing human workers; it’s about creating a synergistic relationship where both can thrive:

- Collaborative Robots (Cobots): These robots are designed to work alongside humans in shared environments. They are equipped with safety features that allow them to operate without barriers. Imagine a factory floor where robots assist workers in heavy lifting, while humans focus on intricate tasks requiring creativity and decision-making.

- Improved Work Environments: Human-robot collaboration can lead to safer work environments. For example, robots can take over dangerous tasks, allowing humans to engage in more cognitive roles, thus reducing fatigue and injury.

- Enhancing Skillsets: As robots take on routine tasks, workers will need to adapt and learn new skills to manage and work effectively with these technologies. This transition encourages continuous learning and innovation within the workforce.

The shift toward effective human-robot collaboration exemplifies the future of work, where technology amplifies human potential rather than replaces it. Embracing these trends will lead to remarkable advancements in capabilities and opportunities across industries!

Resources for Robotics Enthusiasts

Online Communities and Forums

As a budding robotics enthusiast, one of the best ways to enhance your learning experience is by engaging with online communities and forums. These platforms are invaluable for sharing knowledge, seeking advice, and connecting with like-minded individuals. Here are some popular options:

- RobotShop Community: This forum allows you to discuss various robotics topics and get advice on projects. It's an excellent place to share your journey and gain inspiration from others.

- Stack Overflow: While primarily known for software development, Stack Overflow has a wealth of information on programming and robotics. You can ask specific technical questions and get answers from experienced developers.

- Reddit (r/robotics): This subreddit is a hub for robotics enthusiasts. You’ll find discussions, project showcases, and the latest industry news, all in one place.

- Facebook Groups: There are many active Facebook groups dedicated to robotics where members share resources, projects, and tips to help each other grow in this field.

Connecting with these communities can help you stay motivated and gain insights that can fast-track your learning process.

Recommended Reading and Courses

In addition to online interactions, having the right resources for study is crucial. Here are some recommended readings and courses to kickstart your robotics journey:

- Books:

- “Build Your Own Robot” by Marwan Alsabbagh: This book provides a hands-on guide to creating robots using affordable components.

- “Python Robotics”: A great resource for beginners to understand robot programming using Python.

- Online Courses:

- Coursera: Offers various robotics courses from leading institutions like Stanford and University of Pennsylvania, covering basics to advanced robotics concepts.

- edX: Features robotics certifications that focus on specific skills, such as navigation or computer vision.

With these tools and resources at your disposal, you'll be well on your way to making the most of your robotics journey. Establishing a good foundation now will certainly pay off as you explore the fascinating developments in this field! Happy learning.

%20(1).webp)